IN-HOUSE design

The design, build and install of a commercial or residential fire stopping system, whether that be Water Mist or Sprinkler based, is a very complex procedure. The whole process from start to finish is very demanding to say the least, but with skill, expertise and the correct knowhow, the Premiermist team take the procedure in their stride day in and day out.

When designing the layout of the system, each water mist or sprinkler head must be positioned to guarantee that the protected room is covered correctly as well as considering the visual look and the aesthetics of the ceiling as a whole. Following the layout of the heads the pipe routes then need to be planned out along with the type, size and diameter of the pipes. This information is fed into the latest state-of-the-art software where fine tuning is carried to safeguard compliance with the relevant and numerous standards that make up an accredited and true fire stopping system. This process, depending on the size of the project, can take a little as a few hours to weeks conditional on the complexities involved.

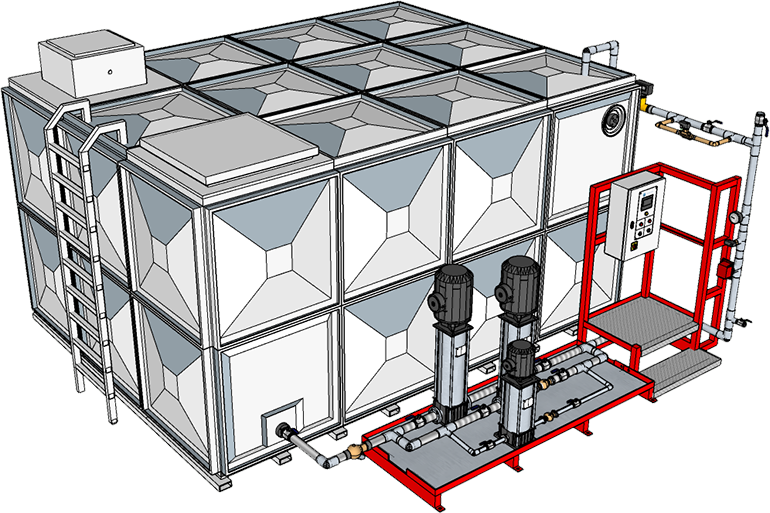

All Premiermist’s designs take into account BS:8458, BS:8489 and any other applicable Standards and technical documents. On receipt of appropriate drawings of the building that is to be protected, our skilled design engineers start by reading the drawings alongside the brief and discussing with senior management about how to add a design that will work within the constraints shown on the drawing. Once a decision has been made water mist or sprinkler heads are added to the drawing in accordance with the BS standards and manufacturers recommendations. Following that the system’s pipe work is added to the design which will connect the heads to the water supply. Our designers will then decide whether to use a Wet or Dry Riser using a direct water supply from an incoming mains pipe or a water storage tank with a fire pump set.

The next stage of the design is to the calculate the FHC (Full Hydraulic Calculations). These are carried out using Canute software, which will govern the design based on the flow and pressure characteristics of the system. The system pipe network is then adjusted by changing the layout, type, size and diameters of the pipe. This safeguards that all the water mist or sprinkler heads in the system design will perform consistent with the relevant British Standard and that the design is the most cost efficient. Usually the drawings that our design team receive include the lighting layout and any other ceiling features, so they can line up the heads with the lighting plan. Any queries or obstacles are taken up with the client and a design is delivered which satisfies all concerned. The designs are then drawn up, printed out electronically, digitally or on hard copy and are then forwarded to the client for approval.

Once the installation has finished, system commissioning will be carried out including a fully comprehensive flow test. The test results are then compared with the design calculations to guarantee full compliance with the design and the relevant BS standards. Following commissioning the design engineers will provide ‘as fitted’ drawings, which will form part of the O&M manual and/or user’s guide.

Any questions? Contact us

Newsletter

Sign up for our newsletter and follow us on social media